Drill bit breakage is a common issue when you are drilling. Broken drill bits can lead to wasted time, increased costs, and even safety risks, all of which is very frustrating. But the good news is, many of these issues are avoidable with the right knowledge.

At Jiacheng Tools, we have over 14 years of experience specializing in high-speed steel (HSS) drill bits and cutting tools. We’ve answered many questions about why drill bits fail. The truth is, even with top-quality drills, breakage can still happen due to improper use. The good news is that a few simple changes can greatly reduce the risk and improve your drilling performance.

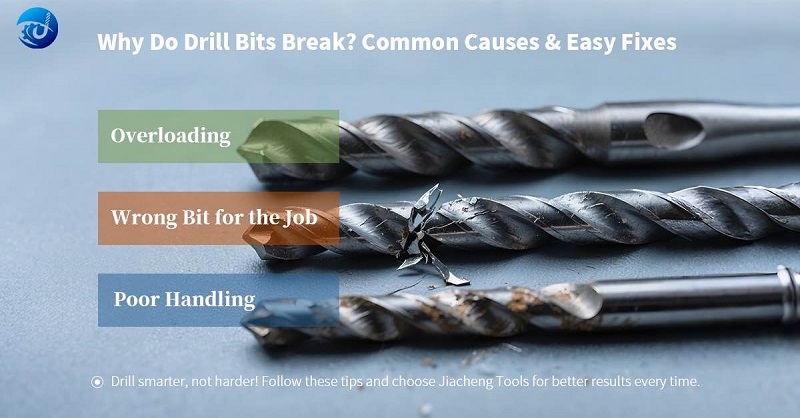

Let’s take a look at the three most common reasons why drill bits break, plus some simple tips to help you get better results and make your bits last longer.

The Common Reasons Why Drill Bits Break

1. Too Much Pressure (As known as Overloading)

The first common reason of breakage is using too much force when drilling. Many users mistakenly believe that applying more pressure will speed up the process. Actually, too much force puts unnecessary stress on the bit, especially during deep hole drilling or in hard materials. Whether you’re using a hand drill or a bench drilling machine, make sure to set the appropriate and steady speed and keep the bit straight and vertical when it touches the material.

2. Overheating During Use

Overheating is another major reason drill bits wear out or break. When you drill continuously without pauses, friction between the bit and the material causes extremely high temperature. This is especially common when drilling metal. Excessive heat can reduce the bit’s hardness, making it more fragile and prone to cracking, bending, or losing cutting efficiency. Many users overlook the importance of cooling, but it plays a critical role in protecting both the drill bit and the material. Try use some cutting fluid, coolant, or oil when drilling hard materials or just simply take a rest to let the drill cool down when you see the drill tip turns red.

3. Using the Wrong Type or Size of Bit

There’re no drills made for all tasks. Using the wrong drill bit for the material is a common mistake that often leads to breakage or poor results. For example, choosing a bit that’s too small or too large for the task can affect both performance and safety. And not all bits are designed to handle every type of surface. Try to use M35 cobalt HSS bits for stainless steel and other tough metals, wood bits for clean and fast cuts in timber, masonry bits when working with concrete, brick, or stone

If you’re unsure which type to use, it’s best to check with your supplier or tool manufacturer for the best recommendation.

Jiacheng Tools: Built for Better Drilling

Avoiding drill bit breakage doesn’t have to be difficult. With the right bit, the right technique, and a little extra care, you can reduce tool failure, save time, and get better results.

Choosing high-quality tools is just as important as using the correct technique. At Jiacheng Tools, we design and manufacture drill bits that are built to handle demanding jobs—crafted from premium-grade materials such as M42, M35, M2 and 4341 high-speed steel, with optional surface coatings to enhance durability and wear resistance.

Whether you’re drilling steel, aluminum, wood, or plastic, our products deliver the reliability, precision, and performance that professionals can count on. Explore our product range or contact our team to find the best drilling solutions for your business.

Post time: Apr-18-2025